Characteristics

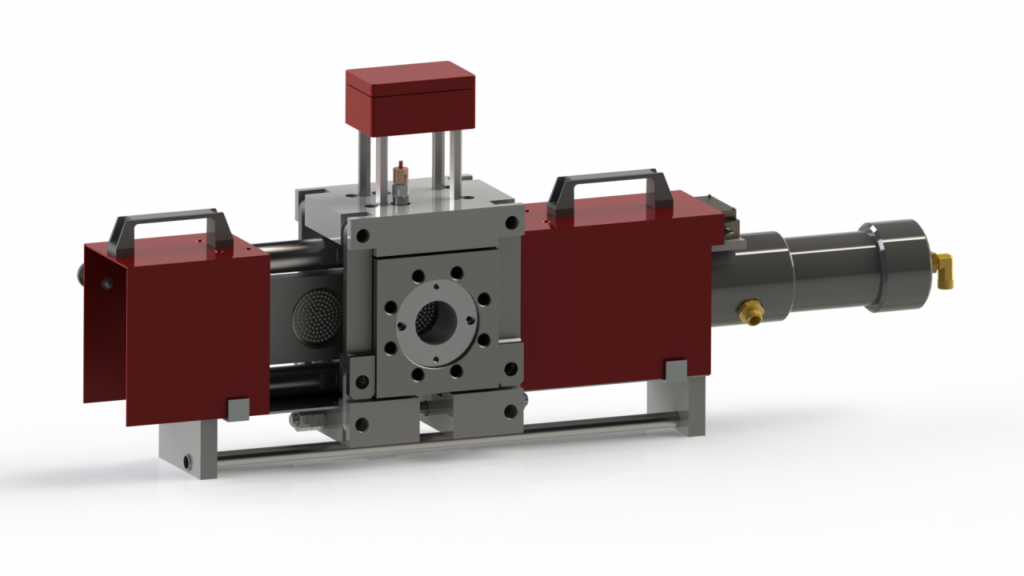

The main element of the screen chanter is sliding plate placed between the two filter blocks. On this sliding plate there are sockets for metal filter screens. These sockets are located eccentrically between the filter blocks. Filtering is carried out on one slot at the time.

Every movement of the sliding disc causes the partial insertion new filter screen into the inlet channel. With this solution, the filtration surface area does not change, which ensures stability of the pressure of the melt. As a result, material parameters do not change during the filtration processs.

Special features

- Constant filtration area,

- constancy of the filtered material parameters,

- large filter area,

- process continuity,

- excellent performance at high temperature of 300°C and at high pressures of 250-300 bar.

- simple to use.

Application for plastics:

- PP – polypropylene

- PE – polyethylene

- PS – polystyrene

- ABS – Acrylonitrile butadiene styrene

- PET – Polyethylene terephthalate

- etc.

| Designation | Filtration area [cm²] | Heaters [kW] | Heating zones | Max pressure [bar] | Weight [kg] |

|---|---|---|---|---|---|

| H50 | 20 | 1,02 | 1 | 500 | 60 |

| H65 | 35 | 1,40 | 1 | 500 | 75 |

| H80 | 50 | 2,80 | 1 | 500 | 120 |

| H95 | 70 | 3,0 | 2 | 350 | 170 |

| H155 | 195 | 8,0 | 2 | 350 | 600 |

| H185 | 285 | 10,0 | 2 | 350 | 1000 |

| H205 | 330 | 12,50 | 2 | 300 | 1300 |

| H255 | 510 | 14,0 | 2 | 250 | 1500 |

| H305 | 730 | 16,0 | 2 | 250 | 1800 |