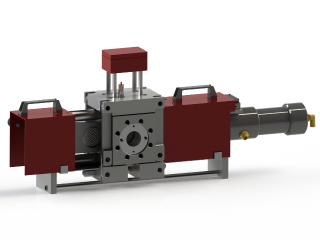

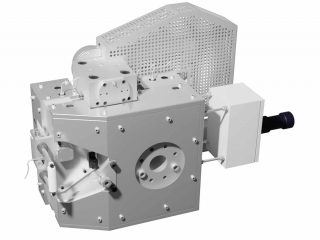

Screen changers

Processing of plastics consists of polymer melting and giving it the desired shape. The melting of plastic process is a relatively simple and mastered in modern extruders or injection molding machines. A method of filtering the melt material is often overlooked in studies. This makes a significant technological problems. Because the wrongly chosen filtering system may result in stopping the production line for replacement of the filter screens. It causes significant unnecessary costs.

Plastic filtration systems can be divided into:

- Permanently installed filter support

- a replaceable sliding single or multi-socket filter charge, constructed as a plate or tang,

- auto-screen system with a sliding filter screen,

- disc system

- systems with and without self-cleaning.

We offer new and used screen changers and repair service for all changers along with complete technical support. We also provide repair service and spare parts for screen changers.

We can deliver every filtration system, depending on individual needs, e.g.:

- simple

- semi-automatic

- automatic and self-cleaning

- 1- and 2-socket sliding plates

- with one or two sliding plates

- 1- and 2-socket pin systems with round or oval nets

- pin systems with one or multiple pins