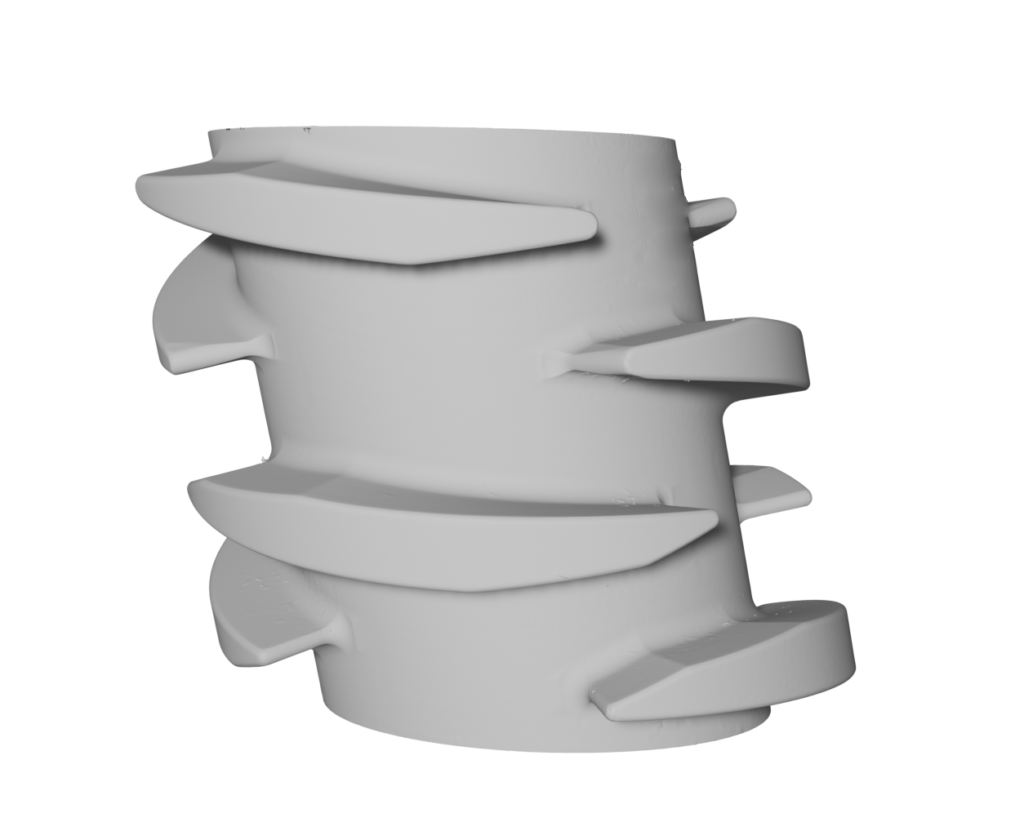

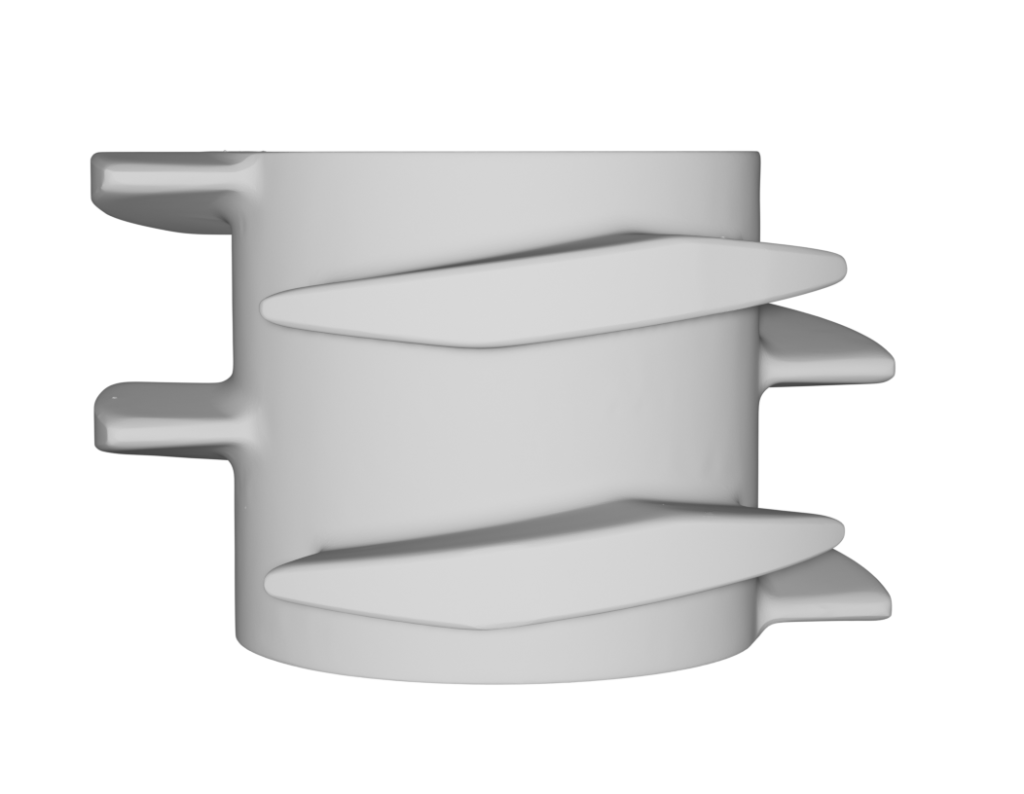

Screw elements

Screws are cylindrical elements with spiral grooves that are placed inside an extruder. During the extrusion process, plastic or rubber pellets are placed in the screws, where they are then gradually moved along the spiral grooves. As the plastic or rubber moves through the screw, it gradually melts and mixes until it reaches the extrusion point.

Performance improvement

Split screws can enhance the extruder’s efficiency by increasing the surface area where mixing, plastic deformation, and the production of the final product occur. With a double thread, they provide more space for material processing compared to single-screw designs.

Better mixing

Thanks to the double-thread design, the material is better mixed and distributed along the length of the screw. This can be especially important for multi-component blends or in cases where additives are involved, as even distribution is crucial for the final product’s quality.

Increased process stability

Split screws can also provide a more stable extrusion process. Thanks to the even distribution of the material and better mixing, there is less risk of areas of variable quality in the final product. Adjustable

Depending on the design, split screws can be designed to allow adjustment of process parameters such as mixing ratio, temperature and rotational speed. This allows for flexible adaptation of the extruder to various materials and production requirements.

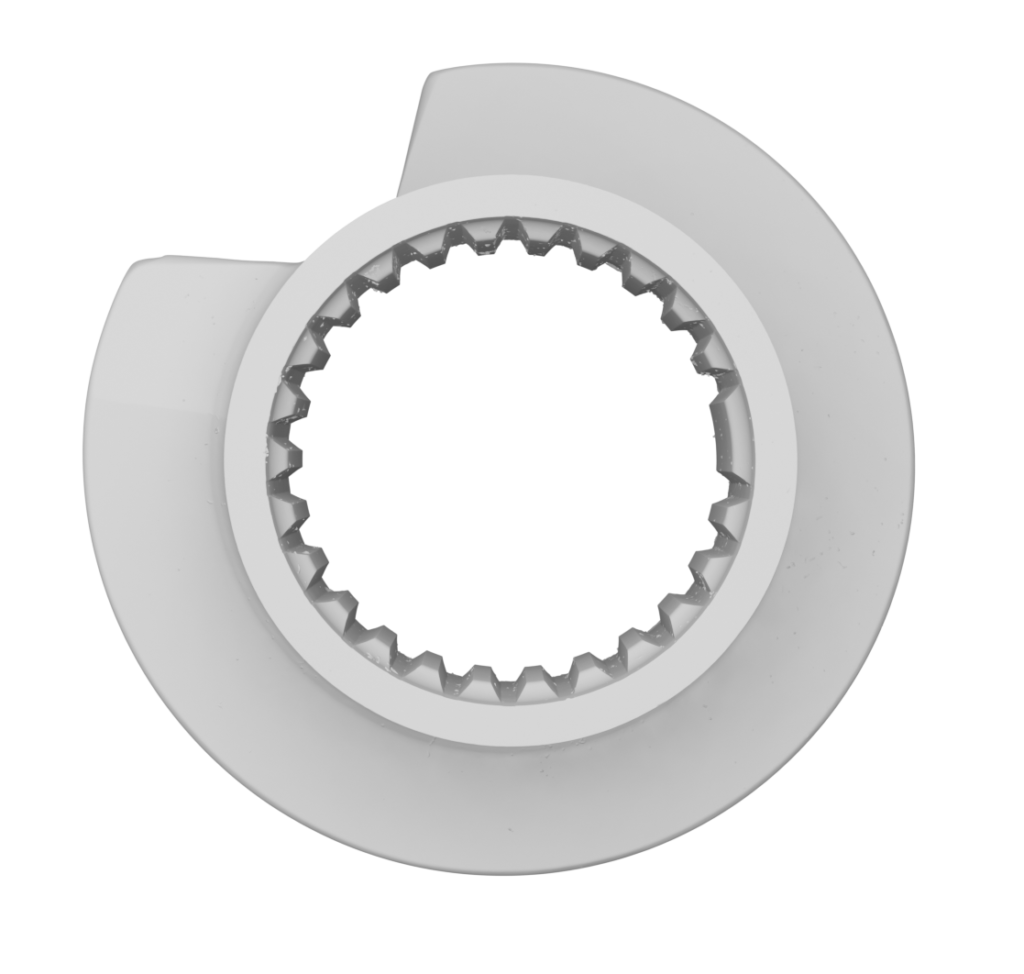

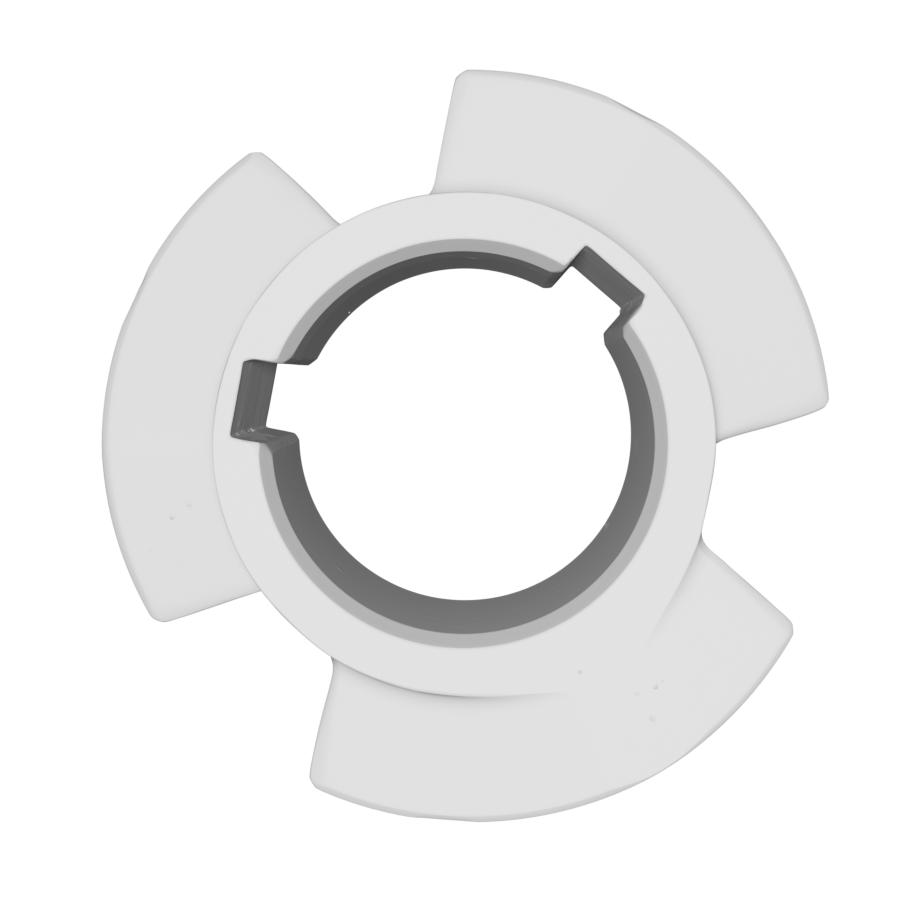

Kneading pins

Kneading pins play a key role in the plastic extrusion process, ensuring effective mixing, kneading and plastic deformation of the material, which leads to high-quality final products and increased efficiency of the production process.

Mixing and kneading the material

The main function of the kneading pins is to mix and knead the material in order to evenly distribute additives, pigments or other ingredients in the plastic mass. These pins generate the appropriate pressure and cutting force that allows for thorough mixing and kneading of the material.

Expansion and plastic deformation of the material

Kneading pins also help in the process of expanding the material, i.e. increasing its volume by using heat and pressure. Moreover, during kneading, the material undergoes plastic deformation, which is necessary to transform it into the appropriate consistency for further processing.